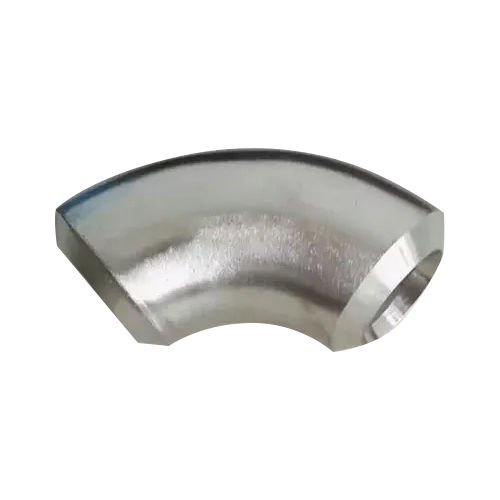

Inconel Nickel Alloy Steel Elbow

Inconel Nickel Alloy Steel Elbow Specification

- Bend Radius

- Short radius (SR) = 1D, Long radius (LR) = 1.5D

- Diameter

- Multiple sizes as per specification

- Tolerance

- Close tolerance as per ASME/ASTM standards

- Flexibility

- Rigid

- Thread Type

- NPT/BSP (threaded option if available)

- Temperature Range

- -196C to +980C

- Yield Strength

- 240 MPa minimum (for Inconel 600)

- Tensile Strength

- 550 MPa minimum (for Inconel 600)

- Connection Type

- Butt-weld, Socket-weld, Threaded (as specified)

- Product Type

- Elbow

- Material

- Nickel

- Connection

- Welded, Seamless (options available)

- Shape

- Elbow (curved/angled pipe fitting)

- Standard

- ASTM B366, ASME SB366 (or as specified by application)

- Surface Treatment

- Polished

- Outer Diameter

- Typically 1/2 to 24 (customizable as needed)

- Section Shape

- Round

- Length

- Varies with elbow type (e.g., short radius, long radius)

- Thickness

- Various available Millimeter (mm)

- Color

- Silver

- Usage

- Industrial piping, chemical processing, high-temperature systems

- Rated Pressure

- Up to Class 2500 (depends on size and type)

- Application

- Oil & gas, aerospace, chemical, power generation

- Material Grade

- Inconel 600/625/800/825 (as specified)

- Additional Product Specifications

- Packaging

- Standard export-worthy packaging

- Availability

- Custom sizes & radii available upon request

- Elbow Angle

- 45, 90, 180 and custom angles available

- Corrosion Resistance

- Excellent against acids, alkalis, and seawater

- Heat Resistance

- Retains strength at high temperatures

- End Type

- Beveled ends (for welding)

- Manufacturing Process

- Cold/Hot formed, Seamless or Welded

- MOQ

- As per manufacturers terms

- Non-Magnetic

- Yes (Inconel alloys are typically non-magnetic)

Inconel Nickel Alloy Steel Elbow Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Inconel Nickel Alloy Steel Elbow

Elevate your piping system with the elite Inconel Nickel Alloy Steel Elbowcrafted masterfully for industries demanding inestimable durability and performance. With sublime corrosion and heat resistance, this elbow thrives in aggressive environments. Shop now and Add to Cart to experience unparalleled reliability in oil & gas, chemical, power generation, and aerospace. Precision-engineered with polished beveled ends, seamless options, and close ASME/ASTM tolerances, these elbows suit diverse custom applications. Manufactured and exported from India, available in various sizes, thicknesses, and radiidesigned for those who accept only the best.

Unmatched Application Versatility & Competitive Advantages

The Inconel Nickel Alloy Steel Elbow is recognized for its exceptional resistance to acids, alkalis, and extreme temperaturesmaking it highly valued for inestimable use in chemical processing, oil & gas installations, and high-temperature power or aerospace systems. Its non-magnetic, polished surface guarantees long-lasting performance with sublime aesthetics. These elbows accommodate aggressive environments and custom requirements, establishing themselves as the preferred, masterful solution wherever demanding performance is needed.

Supply, Sampling & Domestic Market Presence

Estimates for Inconel Nickel Alloy Steel Elbow supply can be provided on request, with standard export-worthy packaging ensuring secure shipment. We offer sample pieces, subject to exchange terms, allowing you to review elite quality before bulk orders. Primarily serving the Indian domestic market, we also export globally, providing reliable fulfillment regardless of project size or industry application. Reach out to discuss your requirements or shop now for immediate needs.

Unmatched Application Versatility & Competitive Advantages

The Inconel Nickel Alloy Steel Elbow is recognized for its exceptional resistance to acids, alkalis, and extreme temperaturesmaking it highly valued for inestimable use in chemical processing, oil & gas installations, and high-temperature power or aerospace systems. Its non-magnetic, polished surface guarantees long-lasting performance with sublime aesthetics. These elbows accommodate aggressive environments and custom requirements, establishing themselves as the preferred, masterful solution wherever demanding performance is needed.

Supply, Sampling & Domestic Market Presence

Estimates for Inconel Nickel Alloy Steel Elbow supply can be provided on request, with standard export-worthy packaging ensuring secure shipment. We offer sample pieces, subject to exchange terms, allowing you to review elite quality before bulk orders. Primarily serving the Indian domestic market, we also export globally, providing reliable fulfillment regardless of project size or industry application. Reach out to discuss your requirements or shop now for immediate needs.

FAQs of Inconel Nickel Alloy Steel Elbow:

Q: How can I customize the angle or size for the Inconel Nickel Alloy Steel Elbow?

A: You can request elbows in standard angles (45, 90, 180) or specify custom angles, diameters, and radii. Simply provide your detailed requirements during ordering for tailor-made fabrication.Q: What is the main benefit of using Inconel Nickel Alloy Steel Elbow in industrial applications?

A: Its masterful resistance to high temperatures, chemical corrosion, and non-magnetic properties make it ideal for challenging environments, ensuring inestimable service life and reliability.Q: When should I consider choosing a seamless versus a welded elbow?

A: Select seamless elbows for higher pressure and purity requirements, while welded options are suitable for general applications with less stringent demands. Both options maintain close ASME/ASTM tolerances.Q: Where is the origin of manufacture for these elbows?

A: All Inconel Nickel Alloy Steel Elbows are manufactured in India, with each batch conforming to international standards and available for export worldwide.Q: What is the process for estimating supply availability and placing bulk orders?

A: Contact us to obtain a supply estimate based on your specifications. Orders are shipped as per MOQ and can include sample elbows for initial review or exchange.Q: How does the unique surface treatment benefit industrial usage?

A: The polished surface treatment enhances corrosion resistance, reduces fouling or contamination, and provides a sublime finish for visible or clean-service pipework.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pipe Fittings Category

Monel Nickel Alloy Pipe Tee

Minimum Order Quantity : 100 Pieces

Standard : Other, ASTM B366, ASME SB366

Color : Silver

Thickness : Various available Millimeter (mm)

Material : Nickel

Nickel 201 Elbow

Price 1500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Standard : ASME, ASTM

Color : Silver

Thickness : Various available Millimeter (mm)

Material : Nickel

Send Inquiry

Send Inquiry Send SMS

Send SMS